Poultry manure is a valuable resource for organic fertilizer production. However, it also contains pathogens, parasites, and odors that can pose environmental and health risks if not properly managed. Composting is an effective way to reduce these risks and produce high-quality organic fertilizer. Composting is a biological process that converts organic matter into humus-like material called compost. Composting requires oxygen, moisture, carbon, nitrogen, and microorganisms to decompose the organic matter. The composting process can be divided into two phases: the thermophilic phase and the maturation phase. The thermophilic phase is characterized by high temperatures (50-70°C) that kill most pathogens and weed seeds. The maturation phase is characterized by lower temperatures (30-40°C) and slower decomposition rates that stabilize the compost and improve its quality.

Top Composters You Can Buy from NPC for Your Poultry Farm Waste Disposal

There are many types of compost equipment that can be used for poultry manure management, depending on the scale, budget, and preference of the farmer. Here are some common types of compost equipment and their advantages and disadvantages:

Groove type compost turner for medium size poultry farms in manure recycling

– Groove type compost turner: This is a machine that moves along a groove and turns the poultry manure pile in the groove. It can mix the manure with straw, sawdust, or other bulking agents to adjust the moisture and carbon-to-nitrogen ratio. It can also aerate the pile and speed up the decomposition process. The advantages of this type of compost turner are that it has a large capacity, low energy consumption, and easy operation. The disadvantages are that it requires a large area, a fixed groove structure, and a high initial investment.

Turn Poultry manure into commercial with NPC Wheel type compost turner at industrial scale

– Wheel type compost turner: This is a machine that moves on wheels and turns the poultry manure pile on the ground. It can also mix and aerate the pile as well as groove type compost turner. The advantages of this type of compost turner are that it has a flexible movement, a simple structure, and a low cost. The disadvantages are that it has a smaller capacity, a higher energy consumption, and a lower turning efficiency than groove type compost turner.

Crawler type compost turner: manage your poultry farm litter at open windrow composting method

– Crawler type compost turner: This is a machine that moves on tracks and turns the poultry manure pile on the ground. It has a similar function as wheel type compost turner but with better stability and adaptability to different terrains. The advantages of this type of compost turner are that it has a moderate capacity, a moderate energy consumption, and a high turning efficiency. The disadvantages are that it has a higher cost and a more complex structure than wheel type compost turner.

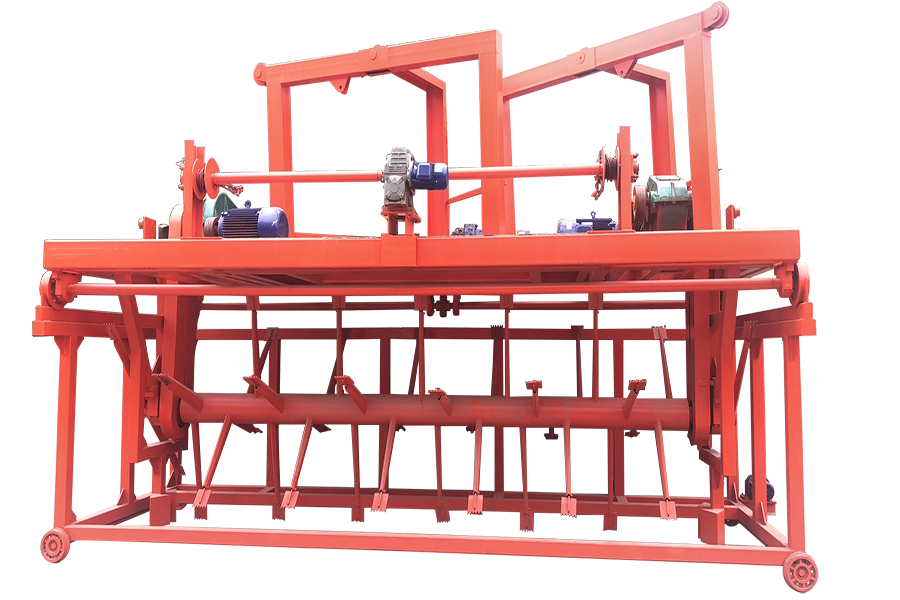

Chain plate type compost turner : Disposal poultry manure throughly

– Chain plate type compost turner: This is a machine that moves on chains and turns the poultry manure pile on the ground. It has a similar function as crawler type compost turner but with more power and durability. The advantages of this type of compost turner are that it has a large capacity, a high turning efficiency, and a long service life. The disadvantages are that it has a high cost, a high energy consumption, and a loud noise.

Fermentation tank: for rapid and automatic poultry waste treatment in 7days

– Fermentation tank: This is a closed container that can control the temperature, moisture, oxygen, and pH of the poultry manure during composting. It can also automatically turn and discharge the compost. The advantages of this type of compost equipment are that it has a fast composting speed, a high quality of compost, and a low odor emission. The disadvantages are that it has a high cost, a high energy consumption, and a limited capacity.

The choice of compost equipment depends on various factors such as the amount of poultry manure, the available space, the budget, and the desired quality of compost. Each type of compost equipment has its own pros and cons, so farmers should weigh them carefully before making a decision.