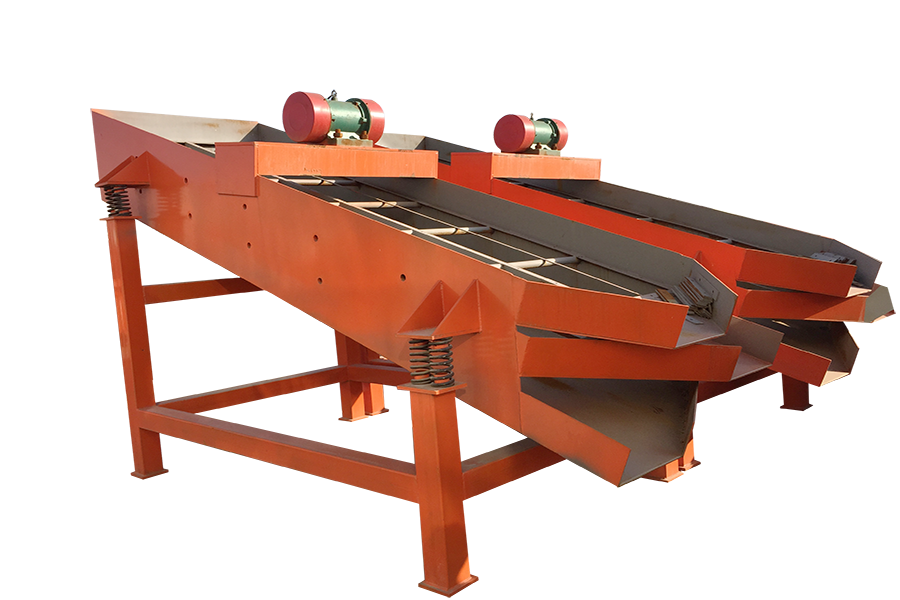

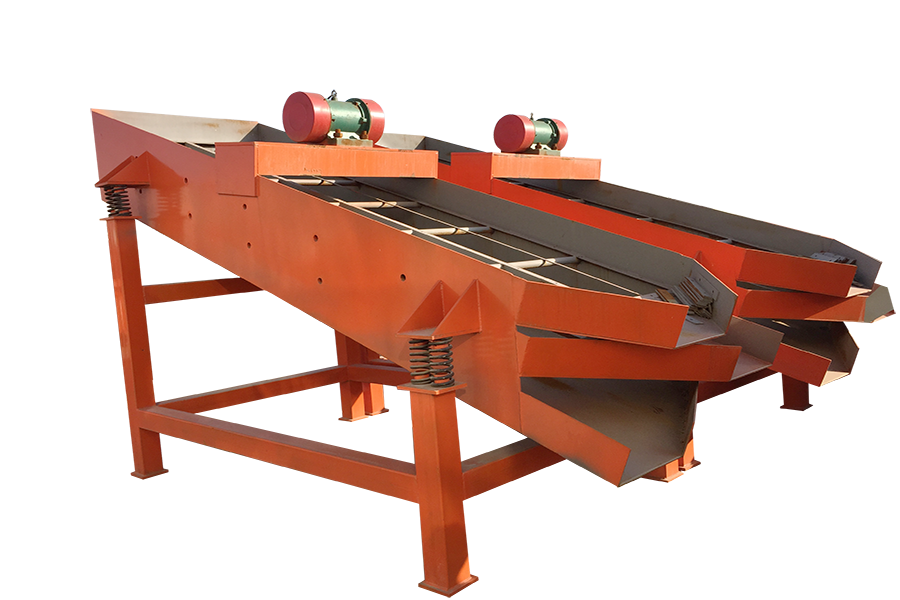

Vibrating Screener for Sale

- Core Components: Motor

- Condition: New

- Application: Ore, silica/quartz sand or other sand

- Voltage: 380V/415V/440V/etc

- Dimension(L*W*H): 1450*4300*1600MM

- Weight: 2200 KG, 1900Kg

- Layer: 2 layers

- Diameter: 1450*4300*1600MM

- Screen mesh: 5-100 mesh

- Capacity: 3-5t/h

- Power: 3.0Kw*2

Get Price Now!

Description

In the npk fertilizer production line, there are higher requirements on the final products. Especially, wen you make npk fertilizer at commercial scale. Usually, when you need to produce fertilizer for sale. The commercial fertilizer has strictly requirements on its particle sizes. 3 to 8mm npk granules are the commercial sizes for sale in the most markets.

Vibrating Screener for sale in npk plant

What’s more, in the npk fertilizer production process, there are also unqualified fertilizer ingredients need to re-granulate again. Thus, to buy a suitable fertilizer machine for the screening process is quite important. The vibrating screener is another top sale fertilizer sieving equipment along with the other rotary drum screener for sale in our factory.

Vibrating Fertilizer Screener for Sale in Compound NPK Fertilizer Production Line

The fertilizer vibration screening equipment is kind of npk plant machine for separating npk compound raw materials. We design it specially for the npk compounds manufacturing process. There are single and double layer seivers in line with the main parts of the vibrator screener. Different from the traditional screeners, we use high quality manganese steel in the screen parts of the vibration fertilizer screening machine. With compact structure, you can use the screening machine easily. To screen different sizes of npk powders nor granules, we can tailor it for you in the screen hole sizes.

Vibrating Screener Working Principle

How does the vibrating screener work in the npk production process? It consists of three main parts: the electric motor, the vibration system, and the screen web.

The power is transmitted from the motor to the driving shaft of the exciter and the gear vibrator (speed ratio is 1). Through the V-belt, so that the three shafts of the fertilizer screener can rotate at the same speed. By this way, the screener can generate the exciting force. From this process, the exciter is connected with the high-strength bolts of the screen box to produce elliptical motion. Then, npk production materials can move elliptically with the high-speed sieve machine on the screen surface, quickly stratifies, penetrates the screen, and moves forward, so as to complete the classification process.