Single Shaft Mixer

- Max. Loading Volume (L):350 L

- Range of Spindle Speed(r.p.m):35 – 40 r.p.m

- Max. Loading Capacity:350L

- Weight (KG):609 KG

- Application:Liquid, Organic Fertilizer Equipment Production

- Voltage:400V

- Dimension(L*W*H):1250*620*1800mm

- Power (kW):11 kW

- Core Components:Motor, Gearbox, Pump, Engine

- Rotation speed:45r/min

- Certification:CE Certificate

Get Price Now!

Description

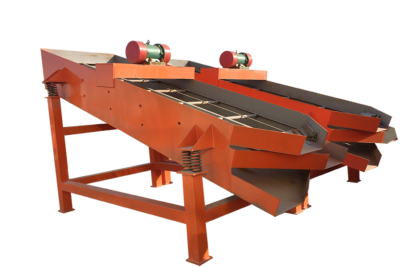

Single Shaft Mixer for sale is suitable for mixing organic npk compound fertilizer blends continuously. In the npk fertilizer production plant, after raw materials automatic batching, then it comes with the fertilizer blending process. In the fertilizer mixing process, the single shaft blender will mix the raw materials in its grooves.

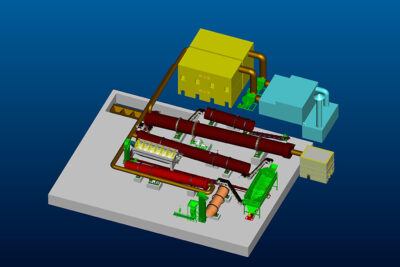

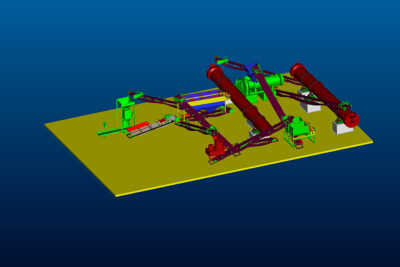

Single Shaft Mixer for sale in npk fertilizer production line

Equipped with a double-ribbon helical blade, it can make fertilizer blends evenly. Thus, it the next npk granulation process easier and more efficient. It is often used in organic fertilizer plants, bio fertilizer production lines, npk fertilizer plants and compound fertilizer plants, etc.

What makes a single shaft mixer top sale fertilizer blending equipment?

(1) It has high stirring efficiency and small footprint. The spiral blades are made of high wear-resistant special alloys.

( 2 ) The single shaft fertilizer mixer is driven by a reducer, with stable rotation and low noise.

(3) The single shaft mixing equipment has a reasonable structure of feeding from the top and discharging from the bottom.

(4) The sealing between the joint surfaces is tight and runs smoothly.

What are the structures of the single shaft fertilizer blender for sale?

The main components of the single mixing equipment are quite simple. But every part we use is in high quality. It includes five main parts. They are single stirring shaft, stirring page, stirring chamber, motor, reducer. Every part of the single shaft fertilizer mixer works together, can help you make quality npk fertilizer blends at a higher working efficiency. The following are its three main parts details:

The single shaft mixer main frame: all the working components of the sing shaft mixer should install on the main structure of the single shaft mixing equipment. Thus, it needs a high-quality frame in manufacturing. We use quality carbon steel plate and channel steel to make the main frame with sophisticated welding process.

The mixing tank. The mixing tank of the single shaft fertilizer mixer is the main containers for npk raw materials continuous blending. With compact structural design, it can help you feed materials fluently in the npk fertilizer production process.

The electric motor. All the fertilizer mixing work should be in electricity power. Thus, equip with a quality brand motor in the single shaft blending fertilizer machine will be a key work in the manufacturing process. Usually, we install quality motor for you with our quality electric motors. If customers need to tailor for you, we will do it for you.

Technical specifications for the single shaft fertilizer mixture production machine

There are different types of single shaft mixers in our factory at factory price. Whether you need to mix composts in your compost production plants, or make granular npk in the compound fertilizer production lines, or produce bb fertilizer in the fertilizer blending plant. In large capacity or small capacity, there always a suitable single shaft fertilizer mixer for you. What type of fertilizer blender do you need for your fertilizer production factory? Want to buy a cost-effective mixing equipment for your fertilizer production line? Get quotations now.