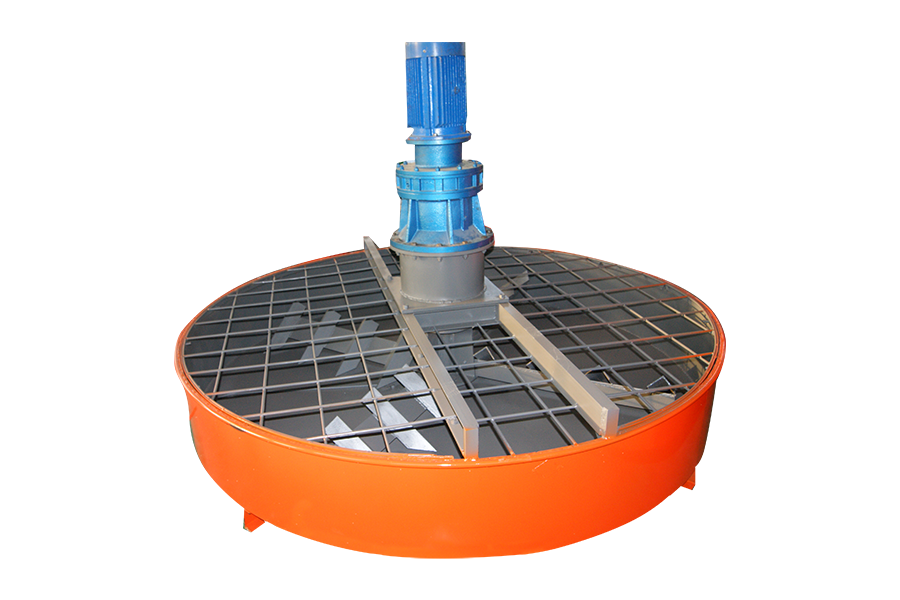

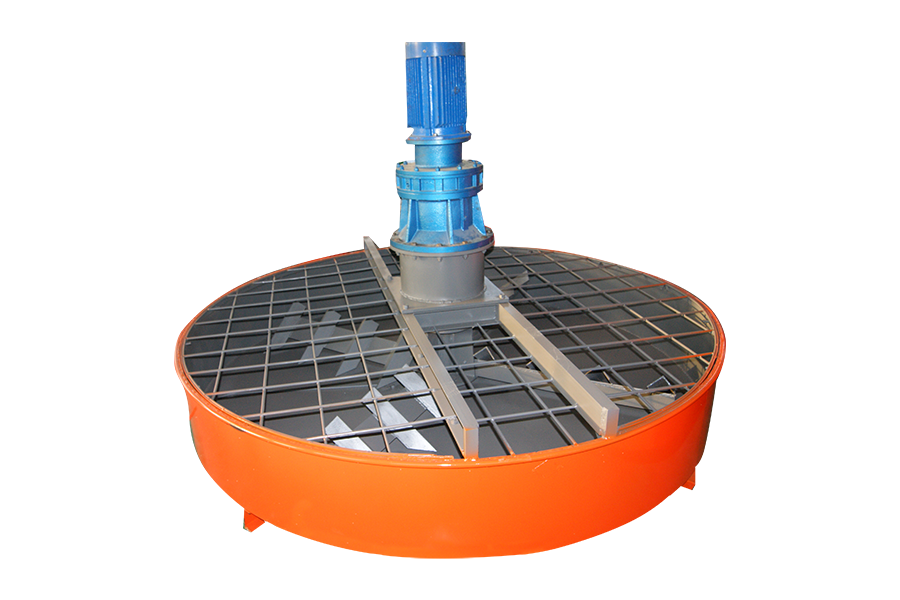

Pan Mixer Machine

- Mixing Power:4.5Kw

- Motor Power:4-7.5kw

- Water Supply Mode:Manual

- Discharge Way:Manual

- Outline Dimension:110*108*108cm

- Warranty:1 Year

- Lead Time:21 days

- Productivity:10M³/H

Get Price Now!

Description

The disc pan mixer machine is a special vertical fertilizer blender for the npk fertilizer production industry. It is a kind of manure mixing equipment specially used for npk organic fertilizer production process. With advanced design concept, compact structure and high practicability, it can help you make npk blends at small scale.

Pan Mixer Machine for Small Capacity NPK Plants

The equipment consists of a stirring plate, a discharge port, a stirring arm, a bracket, a gear box and a transmission mechanism. It has the advantages of long service life, fast stirring speed, high mixing uniformity and thorough discharge.

What is the pan fertilizer blender used for in the npk fertilizer production line?

This pan fertilizer blending machine is a new type of vertical npk mixer, which consists of a mixing disc, a discharge port, a mixing arm, a frame, a gear box and a transmission mechanism. It is characterized in that the output shaft end of the reducer drives the mixing spindle to make it run. There are fixed stirring teeth on the stirring shaft, and the stirring shaft drives the stirring teeth to fully stir and mix the npk materials. The mixer has long life, energy saving, small volume, fast stirring speed, and can work continuously. This mixer machine for npk blending is mainly used for the mixing of raw materials. The inner lining of polypropylene plate or stainless-steel plate can be selected, which is not easy to stick and wear-resistant. And the use of cycloidal pinwheel reducer makes it have the characteristics of compact structure, convenient operation, uniform stirring, convenient discharging and conveying, etc.

Top 3 main components to make up for a quality pan mixer machine

- Frame part: The working body of the machine is installed and fixed on the frame. The frame of the machine is welded with high-quality carbon steel plates and channel steel, and has passed the strict product process requirements and has achieved the purpose of this machine.

- Transmission connection part: The machine adopts cycloidal pinwheel reducer to drive the main shaft to rotate, and the main working part of the machine adopts nylon pins as the transmission connector and the transmission drive, which is convenient for assembly and maintenance;

- The stirring part: it is transmitted to the main shaft by the transmission wheel through the pin coupling. The material is evenly turned in the mixing chamber, so that the material can be mixed, thereby greatly reducing the residual amount of the material.

Technical Data for you to buy a pan fertilizer mixer machine

| Specifications | Power | Capacity | Pan Dia.(mm) | Height(mm) |

| L1600 | 7.5kw | 3-4t/h | 1600 | 400 |

| L1800 | 7.5kw | 4-5t/h | 1800 | 400 |

| L2000 | 11kw | 4-6t/h | 2000 | 400 |

| L2200 | 15kw | 6-10t/h | 2200 | 500 |

| L2500 | 18.5kw | 10-16 t/h | 2500 | 500 |