Compound Fertilizer Production from CMP

-

- Production Capacity: 10,000 to 200,000t Annually Organic NPK Fertilizer Production

- Turnkey Project Solutions:Provided

- Customized Services:Provided

- Installation:Provided

- Main Equipment:Grinder, Blender, Conveyor, Granulator, Dryer and Cooler, Coater, Packer, etc.

Get Price Now!

Description

The physical and chemical principles of the production process

Calcium-magnesium-phosphate fertilizer is a slightly alkaline citrate-soluble phosphate fertilizer, which has special value for acidic soils and soils that need to supplement micronutrients. Generally, it is better than ordinary calcium for yellow soil and sandy fluvo-aquic soil. Therefore, using it to produce compound fertilizer also has its own uniqueness.

Using calcium magnesium phosphate fertilizer as raw material to produce ternary compound fertilizer, sulfuric acid can be used to dissolve part of urea as binder, acid solution such as urea phosphate CO(NH2)2* H3PO4and the alkaline component of tricalcium phosphate in calcium magnesium phosphate fertilizer react.

The solid compound and urea formed by the reaction crystallize after cooling. The calcium magnesium phosphate fertilizer and urea quickly wrap each other and stick to each other into a ball. Under the action of external force, they can grow into particles of the required specifications. When the water content is less than 7%, the particle strength is 10N/grain, the particle size is 1~Amm, and the total nutrient content (N+P2Os+K20)%≥30.

In the production of compound fertilizer with calcium magnesium phosphate fertilizer, sulfuric acid can also be used as a binder, which can be directly sprayed on the mixed material of calcium magnesium phosphate fertilizer and other basic fertilizers. Due to the strong chemical reaction between sulfuric acid and calcium magnesium phosphate fertilizer, a large amount of heat is released, so that the temperature of the material rises rapidly. This heat can be well controlled and the finished product can be dried. This is the basic principle of producing compound fertilizer without drying process.

Calcium magnesium phosphate fertilizer cannot be mixed with ammonium sulfate and ammonium bicarbonate, but can only be mixed with urea. The secondary component of urea is carbonic acid, calcium magnesium phosphate fertilizer is insoluble in water, but soluble in weak acid, which is a weak acid soluble phosphate fertilizer. Urea and calcium-magnesium-phosphate fertilizers release NH4 slowly during the hydrolysis process, which can be well adsorbed by soil, reducing nitrogen loss and enhancing the solubility of calcium-magnesium-phosphate fertilizers.

Adding an appropriate amount of superphosphate to calcium magnesium phosphate fertilizer to produce compound fertilizer can improve fertilizer efficiency. Because superphosphate generally contains about 5% free acid, it will affect the germination of seeds and erode the young roots of crops, and these free acids can be neutralized by adding calcium magnesium phosphate fertilizer. In addition, superphosphate and calcium magnesium phosphate fertilizer are used to produce compound fertilizer, so that the fertilizer maintains part of water-soluble P2Os and part of citric acid-solubleP2O5, which is beneficial to the supply of crops in the early and later stages. At the same time, it also expands the soil application range of fertilizers, not only for acidic soils, but also for alkaline soils. Generally, the mixing ratio of calcium-magnesium-phosphate fertilizer and superphosphate is less than 3:7.

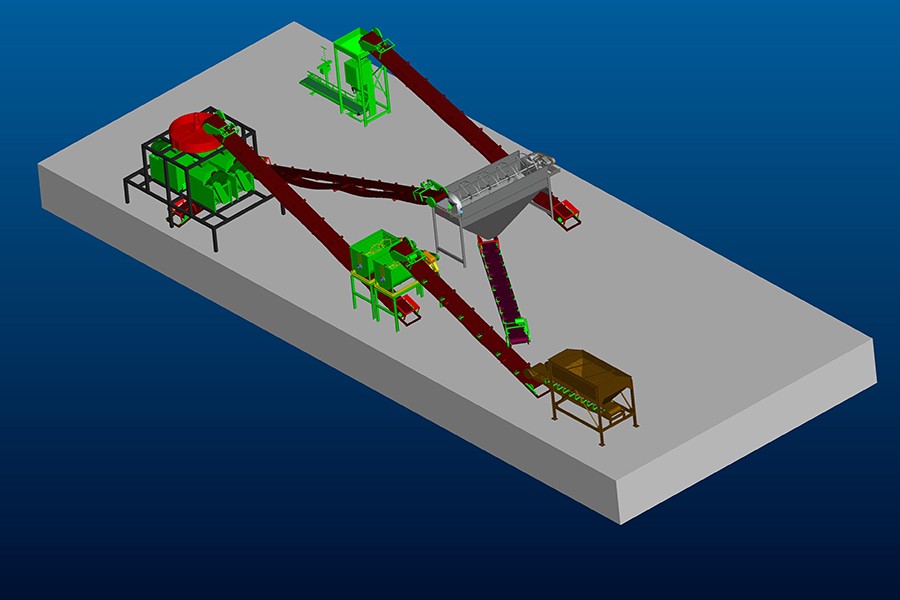

Compound fertilizer production process with calcium magnesium phosphate fertilizer(CMP)

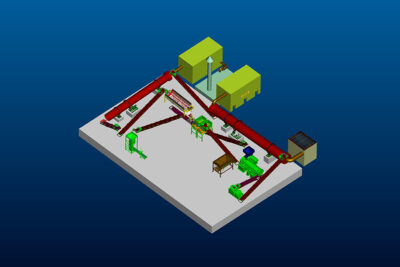

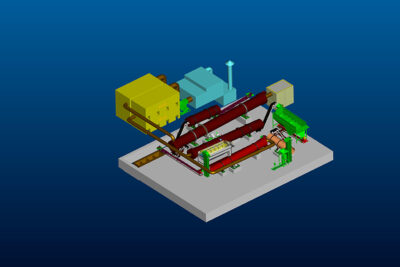

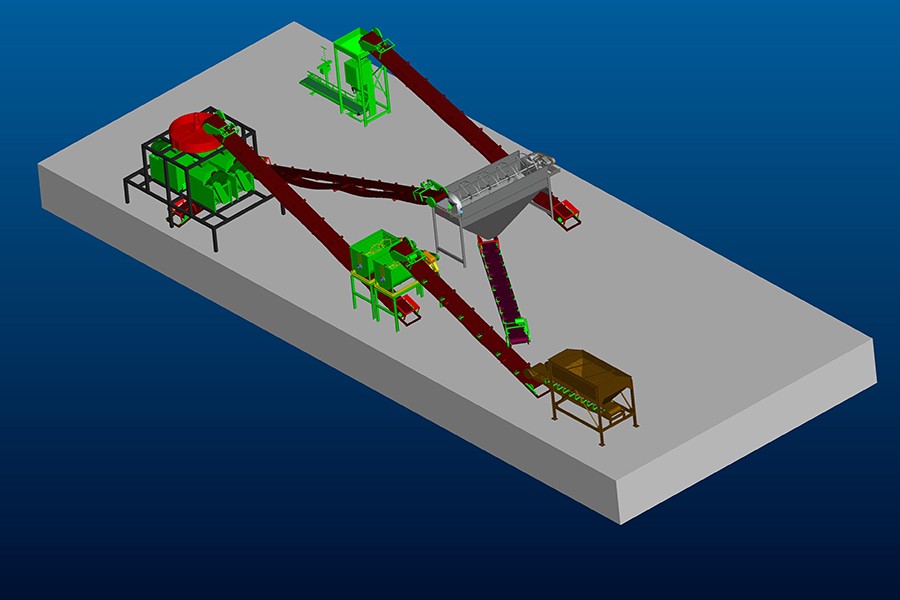

The process of producing compound fertilizer with calcium magnesium phosphate fertilizer without drying is shown in Figure 2-14.

Mix

Various basic fertilizers are metered into the mixer for mixing, and the various materials are stirred until they are completely uniform, which generally takes half an hour.

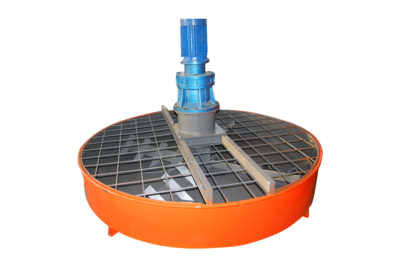

Disc Fertilizer Mixer. This type of mixer has a disc with a central shaft in the center of the disc, and a rake that balances with the bottom of the disc is sleeved on the shaft. When working, the rotation of the central axis drives the rake to rotate, stirring and turning the material. Sometimes, in order to crush the agglomerated particles during the mixing process, a drum is installed in the disc, and the drum crushes the agglomerated particles during operation.

Granulation

In the fertilizer granulator, the raw materials, the returned materials and the added binder are mixed and agglomerated into granules. At the same time, the original material and the adhesive undergo obvious chemical changes, which generate a lot of heat and evaporate the contained water. The type and structure of the granulator are exactly the same as those used in the production of superphosphate.

Sieve /screening

The granular compound fertilizer discharged from the granulator and send it to the rotary drum screener. The particles of 1 ~ 4mm are discharged from the middle as the finished product, and the particles smaller than 1mm and larger than 4mm are discharged from the lower layer and the upper layer respectively, and return to re-granulation.

Coating

Qualified particles screened out should be cooled to dissipate moisture. When necessary, dust the granules with calcium magnesium phosphate fertilizer, or use dry powdery compost or micro-fertilizer as dusting agent to reduce the moisture absorption and agglomeration of the product with the drum coater.

NPK Plant Cost on 1t per hour compound fertilizer production line from Calcium Magnesium Phosphate Fertilizer

Main Fertilizer Equipment Specifications for the NPK Compound Fertilizer Production Line

Main equipment specifications

The main equipment of the 20,000-ton compound fertilizer production line is:

- Diameter: φ2200mm

- Height: 240mm

- Speed: 30r/min

- Installation angle: 60°

- Motor power: 7.5kW, 980r/min

- Diameter: φ1800mm

- Height: 400mm

- Stirring speed: 24r/min

- Motor power: 7.5kW, 980r/min

Vibrating screening machine: 1000×2000, 5 mesh, 14 mesh

Chain mill: motor power: 7.5kW