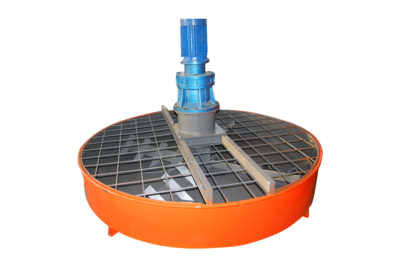

New Type Organic Fertilizer Granulator

- Core Components: PLC, Engine, Bearing, Gear

- Voltage: 380v

- Dimension(L*W*H): 5500*2800*2000mm

- Weight (KG): 2405

- Power (kW): 110

- Raw material: Animal Chicken Manure

- Installation Angle: 2°-2.5°

- Size Of Feeding Material: 50 mesh

- Dimensions: 5500*2800*2000mm

- Capacity: 6-8T/H

- Feature:High Working Efficiency

Get Price Now!

Description

The new organic fertilizer granulator utilizes the mechanical stirring force of high-speed rotation and the resulting aerodynamic force to continuously realize the process of mixing, fertilizer pelleting, spheroidization and densification of fine powder materials in the machine, so as to achieve the purpose of granulation.

The particle shape made by the new type organic fertilizer granulator is spherical, the sphericity is greater than or equal to 0.7, the particle size is generally between 0.3-3 mm, and the granulation rate is greater than or equal to 90%. The size of the particle diameter can be adjusted appropriately by the material mixing amount and the spindle speed.

Usually, the lower the mixing amount, the higher the speed. The higher, the smaller the particles, and vice versa.

Scope of application: This machine is especially suitable for the granulation of light and fine powder materials. The finer the basic particles of the fine powder material, the higher the sphericity of the particles and the better the quality of the ball. Typical application materials: chicken manure, pig manure, cow manure, charcoal, clay, kaolin, etc.

It is specially used for granulation of organic fermented fertilizers with organic fertilizer raw materials such as livestock and poultry manure, composting fertilizers, green manures, sea fertilizers, cake fertilizers, peat, soil and miscellaneous fertilizers, three wastes, microorganisms, etc., the particles are spherulites. The qualified granulation rate of this machine is as high as 80-90%, and it is suitable for a variety of different formulas. The compressive strength of organic fertilizer is higher than that of discs and drums, the rate of large balls is lower than 15%, and the uniformity of particle size can be passed according to user requirements. The machine has stepless speed regulation function adjustment. This machine is suitable for direct granulation of organic fertilizer after fermentation, which saves the drying process and greatly reduces the manufacturing cost. Now this new type of organic fertilizer wet granulator is loved by the majority of users. Our company‘s wet organic fertilizer granulator is in short supply. The birth of new products and new production processes are trustworthy!

What is the structural design of the new type organic fertilizer granulator machine?

This type of fertilizer granulator is composed of motor, transmission, rotor, cylinder and frame.

- It adopts Y series national standard motor, which has the characteristics of strong power, energy saving, reliable quality and overload operation.

- The inside of the reducer is made of special materials and processed by a special process. It has the characteristics of high bearing capacity, stable operation, durable parts and reliable work.

- The rotor is divided into three parts:

① Shaft ② Wing stirrer ③ Wing stirrer head. The shaft is divided into three sections: ① mixing section ②pelletizing section ③ polishing section

The large shaft is made of special materials and specially made. The stirring fin is made of special material, which is hard and wear-resistant, and the length can be adjusted. The stirring fin head is made of alloy steel cutter head.

- The cylinder is divided into three parts: feed mixing section, granulation section and polishing section.

The working principle of the stirring tooth fertilizer granulator machine:

- The organic fertilizer granulator adopts high-speed rotation, and the material is turned over at a high speed with the cylinder, so that the powder can be bonded under high-speed movement, and the processes of mixing, granulation, spheroidization, and densification are continuously realized internally, so as to achieve granulation. the goal of. The particle shape is spherical, the particle size is 0.5mm~5mm, the granulation rate is over 98%, and the moisture content is 35%~40%. The size of the particle diameter can be adjusted by the speed of the rotor. The lower the rotation speed, the larger the particles, the higher the rotation speed, the smaller the particles, and vice versa.

- The organic fertilizer granulator is used to granulate and process the raw materials after fermentation within the specified range. Break through the characteristics of disc granulation, such as large return material, high water content, low strength, uneven particle size, or drying in the air, small output and low yield, and can save fuel in the drying process, breaking through flat film granulation The machine output is low, maintenance is difficult, mold cleaning is difficult, adjustment is troublesome, and it brings labor and time-consuming features to users, which greatly saves energy, improves the utilization rate, improves the profit of the enterprise, and realizes the direct wishes of customers.

Installation and debugging of the stirring tooth granulator:

- Installation: Before installing the machine, a prefabricated concrete table needs to be laid, and the base of the granulator is fixed on the table with anchor screws, which facilitates the operation of the granulator and prevents the granulator from moving. It is also necessary to pay attention to the belt conveyor for conveying materials should be aligned with the inlet and outlet, and can also dig pits for material transportation.

- Debugging: After the granulator is installed, it is necessary to check whether the parts of the granulator are fastened. Then carry out no-load test run, and run no-load operation for 8 hours without interruption. The temperature of each bearing should rise steadily. At the end of the test run, the temperature of each component should not be higher than 50 °C. After the test run, observe that each bearing must not have serious wear and scratches.

Why to buy an organic fertilizer granulator for your fertilizer plants?

Simple principle, fast granulation speed

Using the mechanical stirring force of high-speed rotation and the resulting aerodynamic force, the fine powder material can be continuously mixed, granulated, spheroidized and densified in the machine, so as to achieve the purpose of granulation.

High granulation quality

This machine is especially suitable for the granulation of light and fine powder materials. The finer the basic particles of the fine powder material, the higher the sphericity of the particles and the better the quality of the ball.

No adhesive required

Taking advantage of the fact that organic particles can grow up with each other under a certain force, no binder is required during granulation.

Wide range of material sources

Livestock and poultry manure, horse manure, composting fertilizer, green manure, sea fertilizer, cake fertilizer, peat, soil and miscellaneous fertilizer, three wastes, microorganisms and other municipal solid waste.

Technical specifications for the New developed organic fertilizer granulator

| Model | Feed Particle Size(Mesh) | Moisture | Ggranular Sizes (mm) | Main Body Thickness (mm) | Capacity (t/h) | Reducer Model | Dimensions (mm) |

| JZ-600 | 50 | 20%-40% | 2-5k | 8 | 1-1.5 | ZD25-4.5 | 600×600×800 |

| JZ-800 | 50 | 20%-40% | 2-5 | 8 | 1.5-3 | ZD30-4.5 | 4250×1850×1300 |

| JZ-1000 | 50 | 20%-40% | 2-5 | 10 | 2-5 | ZD40-4.5 | 4700×2350×1600 |

| JZ-1200 | 50 | 20%-40% | 2-5 | 10 | 32 | ZD40-4.5 | 4950×2600×1750 |

| JZ-1500 | 50 | 20%-40% | 2-5 | 12 | 6-8 | ZD45-6.3 | 5500×2800×2000 |