Movable Compost Turner

-

- Core Components: Engine

- Production Capacity: 300-500m3

- Voltage: Customers’ Requirement

- Weight: 1300 KG

- Dimension(L*W*H): Model Decision

- Usage: Animal and poultry manure pile turning machines

- Type: Self-propelled windrow compost turner

- Capacity: 300-500m/h

- Working Width: 2000-3600mm

- Turning Height: 600-800mm

- Certification: ISO9001 CE

Get Price Now!

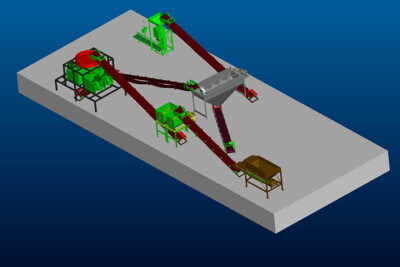

Description

The walking-type or movable compost turner for sale adopts ground stacking and fermentation(windrow composting method), which is currently a relatively advanced fertilizer-making technology that saves civil engineering and human resources.The materials need to be stacked in long strips when using the movable compost turner machine. (Windrow composting method) The decomposition of organic matter is carried out under aerobic conditions. It has the function of crushing, which greatly saves time and labor, greatly improves the production efficiency and product quality of the organic fertilizer plant, and greatly reduces the cost. Some auxiliary facilities can also be added of quality composting, such as automatic sprinkling devices.

Windrow movable compost turner working performance

The walking compost turner (self-propelled portable compost turner) is the main engine in the complete set of equipment for the production of bio-organic fertilizers. Its main features are as follows:

- The fermentation process adopts microbial oxygen-consuming fermentation, which is designed according to the principle of oxygen-consuming fermentation, so that the fermentation bacteria have space to fully exert their functions.

- It is more suitable for the mechanism and process requirements of microbial fermentation of poultry manure into fertilizer, and can effectively mix viscous poultry manure with microbial preparation and straw powder. It creates a better aerobic environment for material fermentation. Under the condition of this loose material, the fermentation temperature of cow dung can be controlled at 60-70 degrees and maintained for 3-4 days.

- The power of the whole machine is balanced and suitable, the energy consumption is low, and the output is large, which reduces the production cost of bio-organic fertilizer. According to the technical parameters of the machine, the small machine can mix 400-500 cubic meters of fresh cow dung per hour (equivalent to 100 people working tirelessly at the same time. workload). There are as many as 4 or 5 employees in the whole factory. Make the finished fertilizer form an obvious price advantage.

- The overall structure of the machine is reasonable, the whole machine has good rigidity, balanced force, concise, strong, safe and reliable performance, easy control, and strong applicability to the site. Except for the thick frame, all parts are standard parts, which are easy to use and maintain.

- How does the movable compost turner work in the windrow composting process?

- This machine adopts four-wheel self-propelled type, which is controlled by one person and applies anti-skid tires. When walking, the whole vehicle rides on the bar-shaped stack, and a new bar-shaped stack is formed after the car passes. The machine can be used in many occasions. It also has a crushing function in the later stage of material fermentation. The overall structure is rigid and the performance is safe and reliable.

The machine adopts a four-wheel walking design, which can move forward, backward, and turn, and is controlled and driven by one person. During driving, the whole vehicle rides on the pre-stacked long strip of fertilizer base, and the rotary cutter shaft mounted under the frame performs mixing, fluffing, and stacking of the fertilizer base raw materials. Shaped stacks. The operation can be carried out in the open field or in the workshop greenhouse.

A major technological breakthrough of this machine is the integration of the crushing function in the later stage of material fermentation. As the material is gradually dehydrated, the cutter shaft equipped with the crushing device can effectively crush the plates formed by the fertilizer during the fermentation process, which not only saves a crusher, but also greatly improves the crushing efficiency and reduces the cost. Therefore, the production volume is limited by the crusher.