Sludge Fertilizer Plant

-

- Production Capacity:1t to 30t Per Hour

- Applicable Materials: Pure Sludge Wastes

- Industry Serviced: Sludge Waste Treatment Plant

- Complete Set of Machine:Provided

- Installation:Provided

- Turnkey Project Solutions:Provided

Get Price Now!

Description

With the development of the world economy and the continuous improvement of people’s living standards, the task of urban sewage treatment has become heavier and heavier. The sludge discharged from urban sewage plants has become an important part of the urban and rural environment. Therefore, the use of sludge to produce compound fertilizer can not only increase fertilizer resources for agriculture, but also solve the problem of secondary pollution of urban sewage, which is of great significance. The composition of sludge discharged from urban sewage plants varies significantly due to different sources of sewage, purification processes and purification conditions. According to the relevant data, the concentration of nitrogen, phosphorus and potassium in the sludge is 5%~7%, the organic matter is 40%~60%, and the harmful substances are usually less. The following are the main components of urban sludge in Suzhou. The moisture content of fresh sludge cake is 75% ~ 80%, and the moisture content is about 15% after natural drying. The contents of other main metal elements are shown in Table 6-22.

It can be seen from Table 6-22 that the sludge discharged from the sewage treatment plant, except for the high content of zinc, which exceeds the control standard, all other metal elements meet the control standard. Zinc is often necessary for the growth of plants. As long as the appropriate amount of fertilization is controlled during the fertilization process, the production of compound fertilizer from sludge will not cause re-pollution problems.

In the sludge production of compound fertilizer, the sun-dried dewatered sludge accounts for 20% to 40%, and other fertilizer nutrients account for 60% to 80%. The indicators of the product are controlled according to the national quality standard of ternary compound fertilizer. Other nutrients of compound fertilizer can generally be selected from urea, ammonium chloride, ammonium sulfate, ammonium bicarbonate, superphosphate, calcium magnesium phosphate fertilizer, potassium chloride, potassium sulfate, etc. In the production process, an appropriate amount of binder and dusting agent should be added to improve the physical state of the fertilizer.

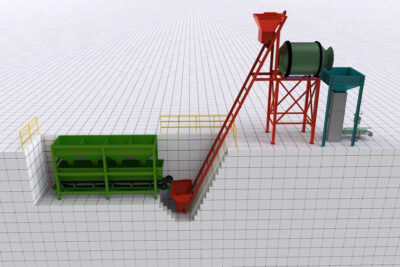

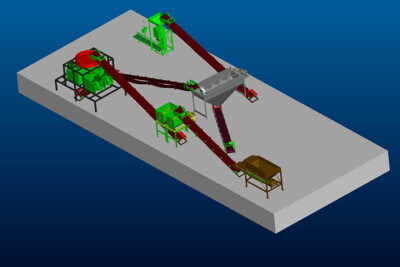

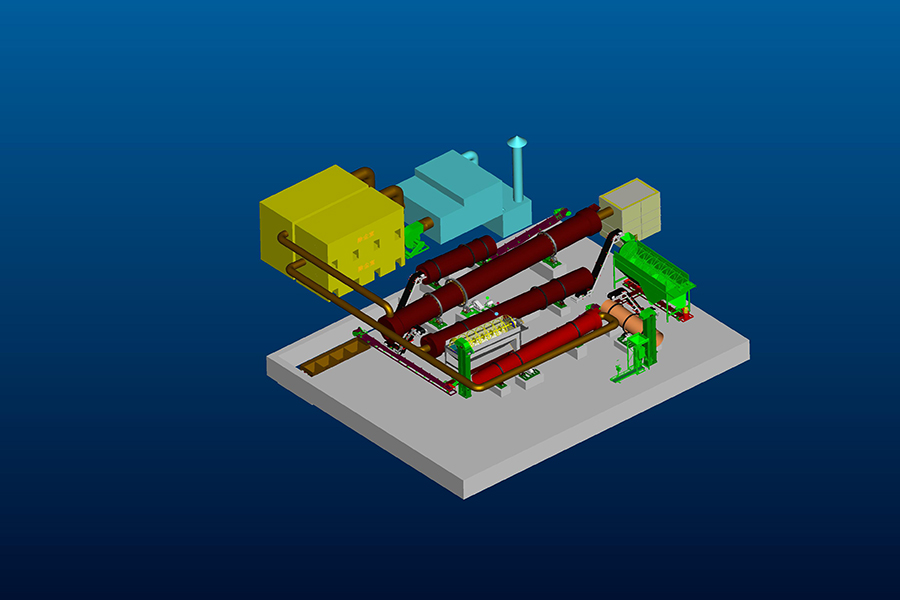

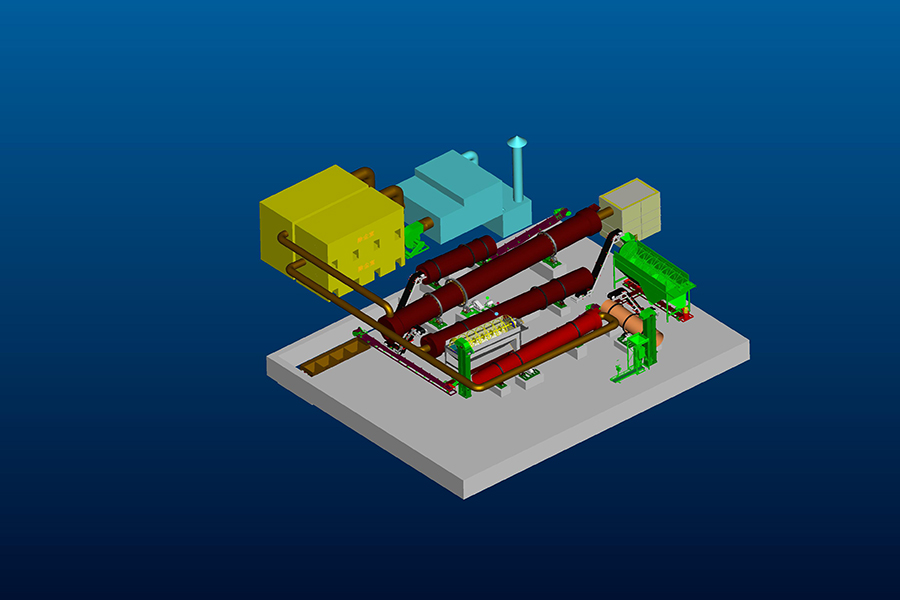

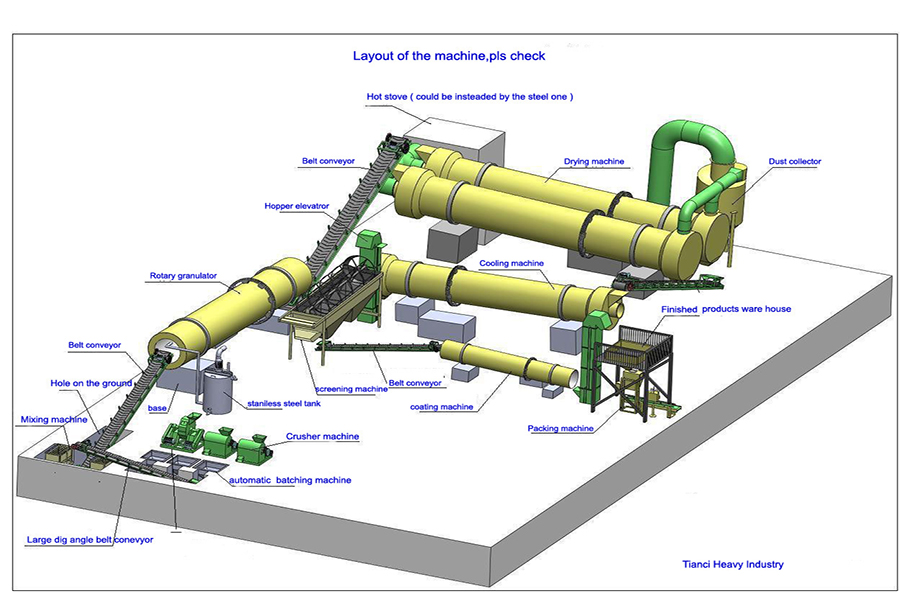

The production process of using sludge to produce organic compound fertilizer is basically the same as that of ordinary ternary compound fertilizer. The process flow is shown in Figure 6-6.

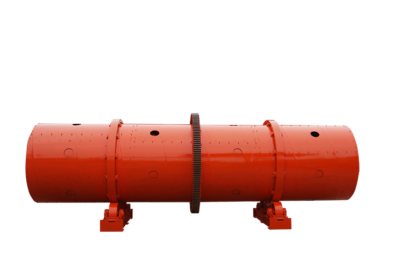

The sun-dried sludge and fertilizers are crushed with a chain pulverizer, graded with a vibrating screen, weighed into the mixer according to the formula, and the mixer is equipped with a fertilizer pelletizer. Granulator for fertilizer granulation. The granulation process is the same as the granulation of ordinary compound fertilizers, and a certain amount of binder needs to be added to make the granules agglomerate and improve the strength of the granules. The compound fertilizer from the granulator can be dried by a rotary drying drum through a dryer. The compound fertilizer from the drying kiln is cooled and sieved, and then the finished product is packaged and shipped. Unqualified products, that is, the particle size is too large or too small. The products are returned to the crushing process for recycling. The prepared material can also be extruded into cylindrical granular compound fertilizer by extruder.

(The pressure is 196MPa), it enters the die hole and is pressed into a cylindrical shape, which is cut by a cutting knife. The product is a cylinder with a length of 5mm and a diameter of 3mm. In extrusion granulation, the material can be heated up by the action of pressure, and then cooled and dried naturally, without a fertilizer dryer, and the strength of the product can also meet the standard requirements. The product quality of various granulation methods is shown in Table 6-23.

The production test results confirmed that when the moisture content of the sludge is about 15%, the material is easier to pulverize, and the mixing performance with other nitrogen, phosphorus and potassium fertilizers is better, and the granulation is better. The granulation rate of the extrusion method is higher than that of the agglomeration method. Under the condition that the product is not dried, the moisture content of the product produced by the extrusion method is lower than that of the agglomeration method. The finished products produced by various methods have good compressive strength. However, which process method is more suitable for production is related to the usage habits of farmers and the actual situation in various places, and should be flexibly grasped.

The application of sludge compound fertilizer is basically the same as that of ordinary organic compound fertilizer. It can be applied alone or in combination with chemical fertilizers and other compound fertilizers. It can be used as top dressing or base fertilizer with good growth effect. The fertilization test results of the sludge compound fertilizer are shown in Table 6-24.