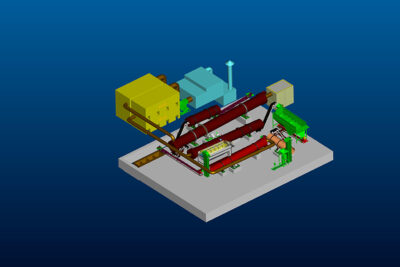

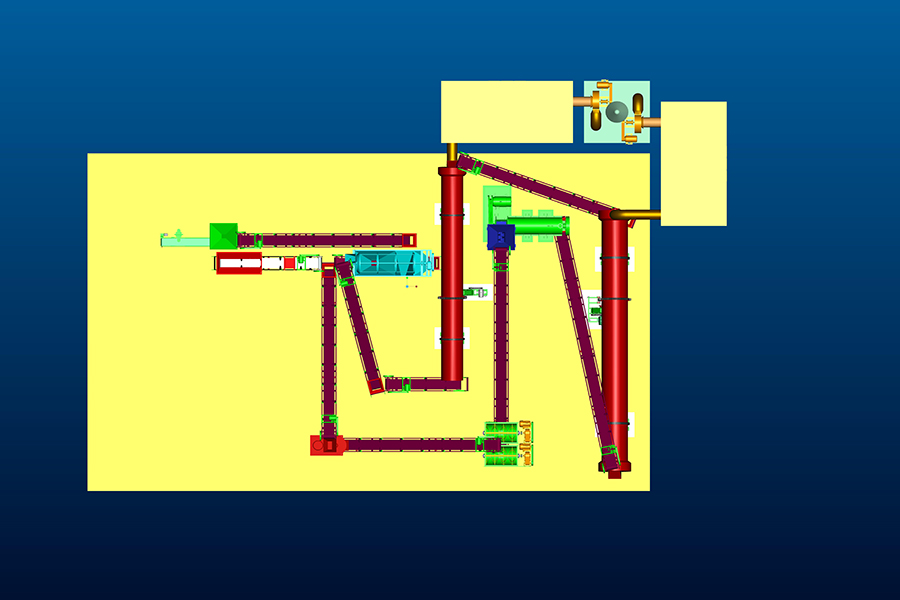

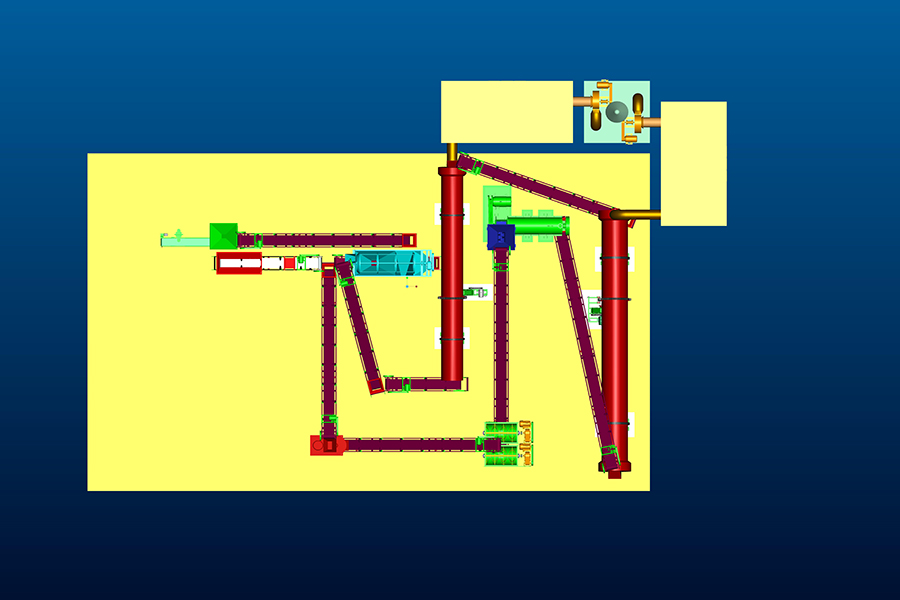

Bran Fertilizer Production Line for Sale

- Production Capacity:1t to 30t Per Hour

- Applicable Materials: Furfural Residues

- Industry Serviced: Furfural Waste Management

- Complete Set of Machine:Provided

- Installation:Provided

- Turnkey Project Solutions:Provided

Get Price Now!

Description

Bran Compound Fertilizer Production Line for Sale

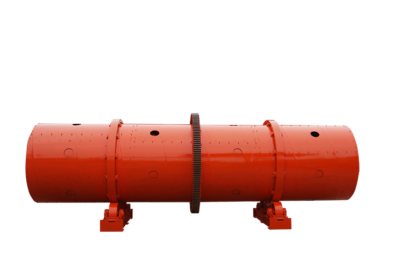

The raw materials of bran fertilizer, except nitrogen, phosphorus and potassium fertilizers, are mainly furfural residues, which are taken from the furfural workshop of the sugar factory. Contains 95% crude organic matter; the total amount of humus is more than 30%; contains N0.5%, P2050.1%, K201.4%, mix the appropriate amount of additives with commercial nitrogen, phosphorus and potassium fertilizers in a certain proportion, and then enter the granulator is used for fertilizer granules making, and the extrusion granulation method can be used. Since the extrusion granulator is not heated by steam like the rotary drum granulator, the extrusion granulator can be cooled by water without decomposing the organic matter. In addition, the bran fertilizer can also be used as a special fertilizer for fruit trees to be made into block fertilizers of different specifications by using a brick making machine.

The other processes and equipment for making compound fertilizer from bran fertilizer are exactly the same as those for making compound fertilizer with salt and tanner. Please refer to the relevant introduction.

Both vegetable experiments showed that bran fertilizer was more productive than peanut cake.

Except for the bran 2 treatment of cabbage, the dry weight yield increase rate was less than 10%, the yield increase rate of each bran fertilizer treatment of the two vegetables was more than 16%, and the highest was 22%, with a large increase in yield. The fertilizer effect of bran fertilizer is greater than that of peanut cake.

Compared with compound fertilizer, the yield of cabbage bran fertilizer treatment was lower, but there was no statistical difference, and the two were quite close. The effect of bran fertilizer application in cabbage is not as significant as that of cabbage, and the yield of bran fertilizer treatment is different from compound fertilizer

The processing gap is large. Because the test soil of cabbage is red soil, lack of P, bran fertilizer contains low P, which is only 1/10 of compound fertilizer. If the proportion of P in bran fertilizer is properly increased, its fertilizer efficiency can be improved and the gap can be narrowed.

Bran Fertilizer Production Process

Bran fertilizer is a great way to enrich your soil and boost your plants’ growth. It is made from furfural residues, which are the by-products of extracting furfural from agricultural wastes. Here are the steps to make your own bran fertilizer from furfural residues:

1. Collect the furfural residues from a furfural plant or a supplier. You can also use corn cobs, oat hulls, wheat straw, or rice husks as raw materials.

2. Dry the furfural residues in the sun or in an oven until they are brittle and easy to crush.

3. Crush the furfural residues into small pieces using a hammer, a blender, or a food processor.

4. Mix the crushed furfural residues with water in a ratio of 1:10. Add some sugar, molasses, or yeast to speed up the fermentation process.

5. Cover the mixture with a cloth and store it in a warm place for about two weeks. Stir it once a day to prevent mold growth.

6. Filter the liquid fertilizer and store it in a sealed container. Use it within six months for best results.

7. Apply the bran fertilizer to your plants by diluting it with water in a ratio of 1:20. Spray it on the leaves or pour it on the roots once every two weeks.

Congratulations! You have made your own bran fertilizer from furfural residues. Enjoy your healthy and happy plants!