Flat Die Pelletizer Machine for Sale

- Raw Material Processed: Grass, Rice Husk, Wood Sawdust, Biomass, Straw, Cotton Stalks

- Pellet Diameter (mm):4 – 6

- Output (kg/h):100 – 300 kg/h

- Voltage:380v/50HZ/3 Phase

- Dimension(L*W*H):1600*900*520

- Weight (KG):410 KG

- Core Components:Bearing, Motor

- Spare Parts:Flat Die +rollers

Get Price Now!

Description

This flat die pelletizer machine is one of the main (biological) organic fertilizer production equipment currently produced by our company. The machine has excellent craftsmanship, simple operation, and various models of different models are designed. It is an ideal fertilizer pellet processing machine for fertilizer processing plants.

/p>

Technical features for flat die fertilizer granulation equipment

- The machine is mainly used for particle manure processing in (bio)organic fertilizer and aquaculture processing industries;

- The granular material processed by this machine has a smooth surface, moderate hardness, low temperature rises during processing, and can better maintain the nutrients inside the raw material;

- The particle composition is uniform, the shape is neat, and the pore size of the particle size can be divided into: 2, medium 2.5, medium 3.5, 4, 5, 6, 7, φ8, etc. Users can choose according to production needs when ordering;

- Due to the low moisture content of the particles, it is easy to store, and can remain in the original state for a long time in water, which greatly improves the utilization rate of materials.

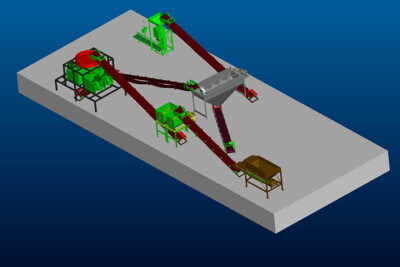

Flat die granulation process

The organic fertilizer flat die granulator process includes the following equipment: pulverizer, belt conveyor, blender, flat film extrusion granulator, dryer, cooler, screening machine, finished product warehouse, packaging machine.

The organic fertilizer flat die granulator is used to granulate various organic fertilizers after fermentation, breaking through the conventional organic granulation process. Before granulation, there is no need to dry and pulverize the raw materials, and the ingredients can be processed directly.

Cylindrical particles can be produced, which can save a lot of energy.

Technical structure for the flat die granulation equipment for sale

The flat mode extrusion granulator plant is mainly composed of a feeding hopper, a pressing roller, a die orifice plate, a gearbox, a motor and a frame, and the structure is shown in Figure 3A. The motor transmits the power to the gearbox through a set of bevel gears to change the steering, drive the flat die or the pressing roller to rotate, realize the relative movement of the pressing roller and the flat die, and squeeze the powder material into the die hole of the flat die. There is a cutter below the die hole that rotates at a low speed to cut the extruded columnar fertilizer to the required length. The flat die extrusion equipment has a simple structure, strong adaptability, uniform particle composition and neat shape, and is suitable for granulation of carbon-based fertilizers containing many fibers (Fig. 3B).

The moisture content in the material has a great influence on the pressurization effect of the flat mode. The study found that the moisture in the mixed material should be controlled between 8% and 10%. If the moisture content is too low, the materials cannot be well bonded. The surface is rough, the strength is not high, the output is low, and the load of the main machine is large; if the moisture content is too high, the particles are easily deformed, extruded into a group, and in severe cases, the entire granulation chamber will be covered. The production capacity of the flat mode extrusion granulator is generally 0.5 ~ 7.0t/h, and the power consumption is 18.5 ~ 110.0kw. From the standpoint of a single machine, the unit energy consumption is higher than that of the roller extrusion granulator.

How to make quality fertilizer pellets with the flat die granulation machine?

The rotating speed and material characteristics are the main factors affecting the granulation of the flat die pelletizer. The research found that the rotating speed of the rolling is generally between 0.6 and 1.2 m/s. If the rotating speed is too fast, the degassing effect during the extrusion process will be poor. The particles are easily broken and the strength is not high. The study found that in order to enter the bite zone, the material must have good fluidity, which requires the material to have a low moisture content. Of course, not absolutely dry raw materials are the most ideal, usually the moisture content of materials is between 0.5% and 2%.

The compression ratio of the extrusion molding process shall not be greater than 2.5. That is to say, during the extrusion process, the volume of the excluded air should not exceed 60% of the bulk volume of the raw materials, and the particle size is usually less than 1mm. For the existing double-roll extrusion granulator, the spheroidization rate is basically above 90%, the average compressive strength of the particles is greater than or equal to 8N, the production capacity is 1-10t/h, and the power consumption is 4-80kw. In terms of energy consumption, it belongs to the low energy consumption and high output model.

Technical Specifications for the flat die fertilizer pelleting machine

| Model | PMZL-150c | PMZL-250c | PMZL-300c | PMZL-350c | PMZL-400c |

| Capacity t/h | 0.08-0.1 | 0.5-0.7 | 0.8-1.0 | 1.1-1.8 | 1.8-2.5 |

| Granulation | >95 | >95 | >95 | >95 | >95 |

| Temperature℃ | <30 | <30 | <30 | <30 | <30 |

| Power KW | 5.5 | 15 | 22 | 30 | 30 |