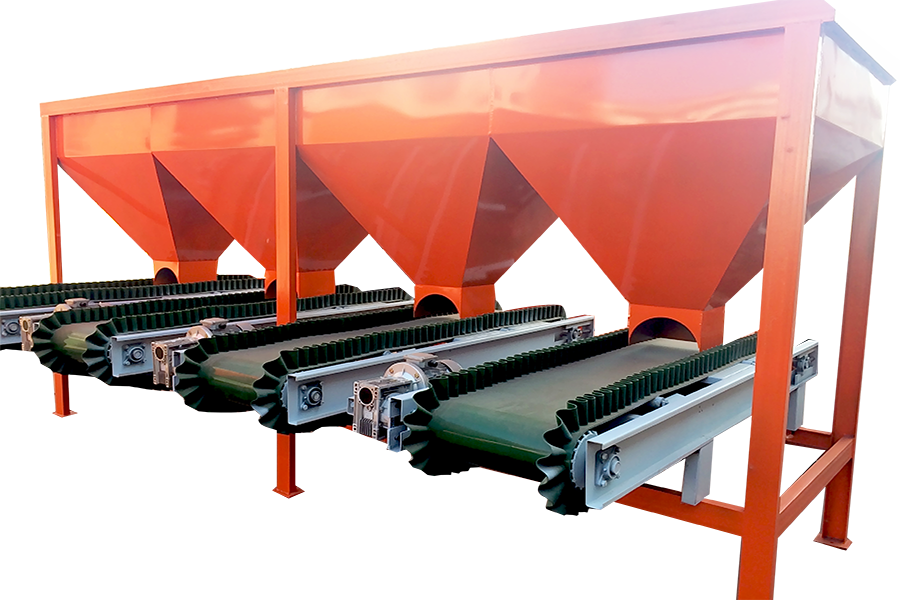

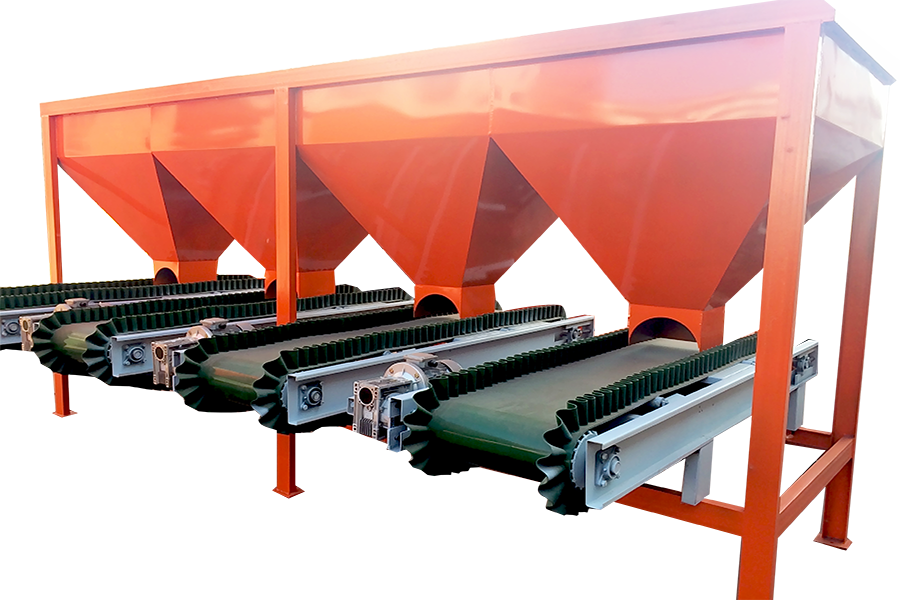

Dynamic Batch Machine

-

- Production Capacity: 1-30t per hour

- Applicable Materials:animal amure, organic bio, micro compound fertilizer ingredients, etc.

- Applicable Industries:NPK Fertilizer Plants, Organic Fertilizer Production Lines, Bulk Blending Fertilizer Plants, Bio Fertilizer Production Lines

- Core Components:PLC, Motor, Engine,Bearing

- Batching Materials Types:3-10

Get Price Now!

Description

Dynamic batching machine is suitable for continuous fertilizer batching requirements in the npk fertilizer plant. In the organic compound npk fertilizer production line, it has high requirements on the continuity of fertilizer ingredients feeding. Generally, you cannot stop any fertilizer production process, to wait the fertilizer, which is very poor in the working efficiency. Moreover, the most important is that it needs to make quality npk fertilizer products with different types of nutrients-based fertilizer ingredients. Thus, to meet stricter requirements on the ratio of various materials in fertilizer production, buying a dynamic batching equipment is necessary. The dynamic batching system mainly includes the measurement scale system and the engine control system. It uses electronic belt scale or the nuclear scale for precise material batching in the measurement system. In the main engine driving system, it adopts PID adjustment system, which can let you batching materials automatically. With alarm function the control system, you can use it more easily.

Top 4 advanced technological designs in the dynamic fertilizer batching machinery

1.Mitsubishi series programmable logic controller (PLC) as the core, which is small in size, high in precision and stable in fertilizer ingredients batching.

2. Multiple scales simultaneous control system, different batching materials can be out at the same time (depending on the fertilizer process)

3. Equipped with a powerful report function system, which can record and store various data. Buy this way, you can use tabulate printing in large quantities. After finishing the batching process, all the detailed batching information, like time, date, and very fertilizer ingredients consumptions, shall be included in the batching report. You can look the report from the PC at any time.

4. Strong PLC Data Processing Ability. With fast and stable sampling rate, which makes the batching process can fully meet the batching requirements for your fertilizer production lines.

Dynamic Fertilizer Batcher Working Principle

When batching raw materials in the fertilizer production process, the electronic screw batching scale will calculate the ingredients first.

Then, the computer will turn the data from the scale into cumulative value and instantaneous flow.

The next process, the RS-485 batching hopper will transfer the data in to the feeding machine.

In the whole batching process, the system will transfer all data into the frequency converter by 4~20mA analog current signal.

Then the converter will adjust the batching speed of the feeding equipment. This technical processing design makes the fertilizer batching process more precise and efficient. You can make different types of npk fertilizer, like npk 15 15 15, npk 19 19 19 or the like with a dynamic fertilizer batching equipment for your project.

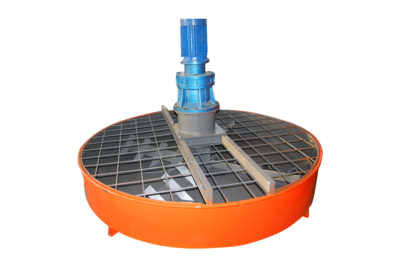

Along with the fertilizer batching machine, there are some other fertilizer equipment for your npk plant. They are fertilizer mixers after batching. For more details, welcome enquire us now.