Dryer Cooler for Sale

- Application: Medicine Processing, Chemicals Processing, Food Processing, fertilizer

- Voltage: 220v/380v

- Power: 5.5kw

- Dimension(L*W*H): 10×1.3×1.3m

- Weight (KG): 8000

- Core Components: Bearing, Gearbox

- Evaporation Capacity(kg/h): 1000

- Heating Method: Gas Heating

- Material: Other, Carbon Steel

Get Price Now!

Description

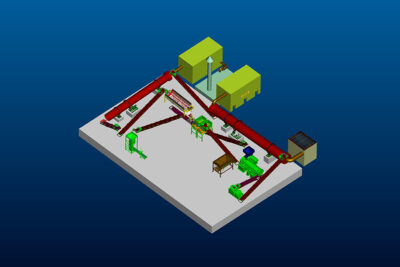

Dryer cooler is two types of fertilizer production machines for customers npk fertilizer production plant. One is the rotary dryers for sale, and the other one is the drum coolers. In npk fertilizer production process, since there are majority of customers using wet granulation technology for large capacity compound fertilizer production, the drum dryer and cooler are very necessary for customers npk fertilizer production project business.

Dryer Cooler for Sale in NPK Fertilizer Plants

By equipping drum cooling equipment in your fertilizer production line, you need to configure a natural gas burner or hot blast furnace to provide energy for the drum dryer and cooler machine.

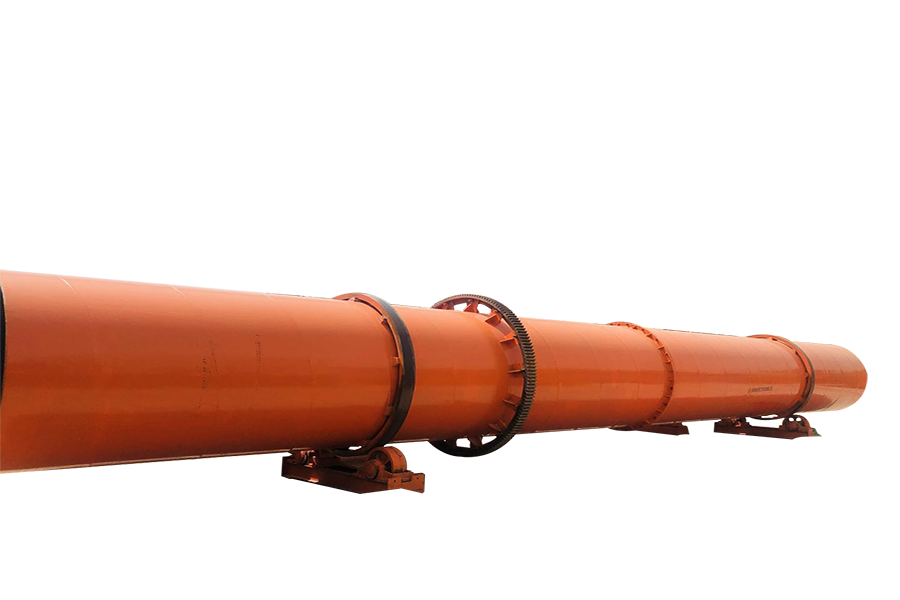

Rotary drum dryer for sale in npk fertilizer production plant

Rotary Drum Drying Machine is suitable for drying different types of raw materials or final products for organic compound fertilizer production. Organic materials, like animal manure, saw dust, sugar mill waste. NPK compound fertilizer materials drying like slag, clay, limestone, gypsum, phosphor gypsum, steel plant slag, power plant slime and sew age treatment plant sludge, etc. Designed with large capacity, you can dry raw materials and final npk compound fertilizers at large capacity.

Rotary Cooler Machines for Dried NPK Granules Cooling

The cooler drum in our factory always cool compound fertilizer npk granules after drying. After drying, there are waters in the granular fertilizers’ surface. Thus, for long time fertilizer storing and packaging, it needs to cool the dry fertilizers first. Along with the drum rotary dryer, it can help customers make quality npk compound fertilizer products efficiently.

Dryer Cooler Technical Specifications

Natural Gas Burner Associated with the fertilizer dryer

When drying organic compound fertilizer products or raw materials, there are some types of auxiliary devices to provide energy to the rotary drum dryer. While, the natural gas burner is the one. It uses the natural gas for fueling as the power energy which is eco-friendly. Customers need to dry materials without pollution, this one will be your nice choice.

Hot Blast Furnace for sale in the rotary drum drying process

Lined with manganese steel plate and firebrick, the hot blast furnace which is convenient for users to hoist and install at any time in their npk fertilizer production line. To meet customers different requirements on the fertilizer production capacities, there are also various types of dryer cooler blast furnaces for your reference.

Apart from the above furnace and burner for the drying drum, there is inducing fun should equip for your drum coolers also. For more detailed info on the dryer cooler fertilizer production equipment in your npk plant project, welcome contact now.