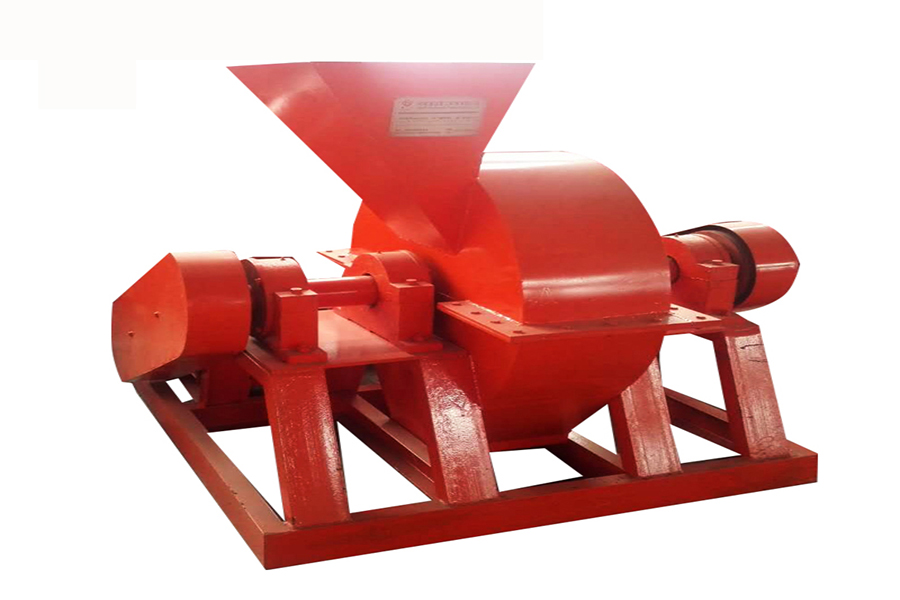

Cage Crusher for Sale

- Motor Type: AC Motor

- Capacity(t/h): 4-6t/h

- Dimension(L*W*H): 1500*1500*1500mm

- Weight: 500 KG

- Warranty of core components: 1 Year

- Core Components: Motor

- Size of inlet: 380*320mm

- Raw Material: Organic Manure

- Key Words: crusher machine

- Usage: Raw Material Grinding

Get Price Now!

Description

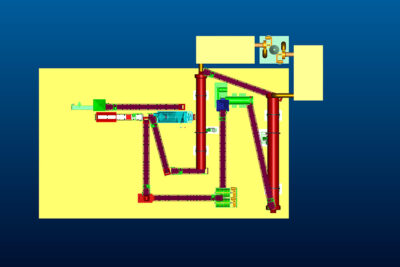

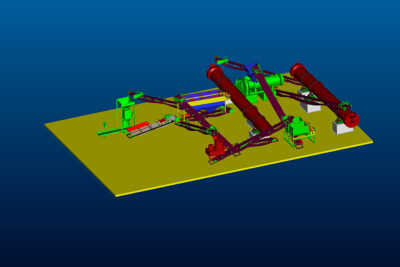

The cage crusher is a medium-sized horizontal type fertilizer crusher. The machine is designed according to the principle of impact crushing. The inner and outer groups of cage bars rotate in opposite directions at a high speed, and the npk materials are crushed by the impact of the cage bars from the inside to the outside.

Cage Crusher has a simple structure, high crushing efficiency, good sealing performance, stable operation and easy to clean and maintain. The cage pulverizer can grind various single chemical fertilizers with a moisture content below 6%, especially for materials with high hardness. It has simple and compact structure, small footprint. for monoammonium, diammonium, urea and other hard granular materials grinding, it is the best choice in your npk plant.

How to use the cage fertilizer crusher before use? First, place it at a certain position in the npk production workshop. It can be used without equipment foundation and connected to the power supply. The fineness of the crushing is controlled by the distance between the double rollers. The smaller the distance, the finer the fineness. The output is relatively reduced, the better the feeding effect is evenly crushed, and the output is relatively increased. This equipment can be designed as a mobile type according to user requirements, and the user can move the corresponding position when using it, and move it away when not in use, which is very convenient.

Right ways to use the cage fertiliser grinder

When you finish the installation and debugging work to the cage crusher, please read the product manual carefully before using it. It will help you understand the structure principle of the crusher. You will be familiar with the performance and operation rules of the cage crusher. Then you should operate it in strict accordance with the operation rules.Meanwhile, conduct patrol inspections in accordance with operating procedures and precautions.

Technical parameters of cage crusher

- Feed particle size: average <ф6-500px;

- Discharge particle size: <0.5mm up to 80%;

- Allowable feed humidity: ≤40%.

Tips for cage mills daily maintenance

To let you use the npk cage crusher for a long time, we provide you the following 12 tips to help you maintain it daily.

(1) The cage crusher motor has been sealed before leaving the factory, and the coupling has been calibrated. Please do not loosen it;

(2) Regularly clean the iron impurities on the permanent magnet cylinder and the permanent magnet plate of the cage pulverizer’s feeder;

(3) Regularly check the fineness of the crushed products;

(4) Regularly clean or replace the dust collector bag (to ensure that the bag is breathable), and regularly check the working condition of the solenoid valve (to see if it can work normally);

(5) Regularly check the wear of the wearing parts of the pulverizer to see if it is normal wear;

(6) Always pay attention to the vibration of the pulverizer;

(7) When the hammers of the crusher are seriously worn and need to be replaced, pay attention to weighing to ensure that the weight difference between the two opposite hammers on the two opposite (1800 direction) hammer pin shafts is ≤ 1g and the two opposite (1800 direction) hammers. The total weight difference of the hammer on the pin shaft is less than or equal to 2g;

(8) When the screen of the crusher is seriously worn and needs to be replaced, pay attention to whether the flatness of the new screen and the size of the screen are reasonable, and whether the installation is in place. It is best to make the screen wool face inward during installation;

(9) The opening degree of the supplementary air door of the impeller feeder should be adjusted properly;

(10) If abnormal conditions such as large vibration and high noise of the pulverizer are found, it should be stopped immediately for inspection;

(11) 80 grams of grease should be added to the main shaft bearing after every 40 hours of operation, but only to 60%. After 1800 hours of operation, the bearing housing cover should be removed and all used grease should be replaced. When replacing with fresh grease, add grease to the area around the rollers and bearing rings, and add 1/3 to 1/2 of the grease to the bottom box, do not add too much grease;

(12) When it is found that the output of the pulverizer has dropped suddenly, in addition to the factors of raw materials, it is necessary to check whether the air supplementary door is in place, whether the pipeline is leaking, whether the pulse cloth bag is blocked, whether the solenoid valve and fan are in place, work normally etc.