Compound fertilizers are a type of fertilizer that contain two or more nutrients, such as nitrogen, phosphorus and potassium. They are widely used in agriculture to improve crop yield and quality. However, producing compound fertilizers requires a lot of equipment, raw materials and expertise. In this blog post, we will explain how to establish a factory to produce compound fertilizers, from planning to operation.

Planning stage

The first step is to conduct a feasibility study to determine the market demand, the potential location, the required capital and the expected profit of the factory. The feasibility study should also include an environmental impact assessment, a legal compliance analysis and a risk management plan. The feasibility study will help you decide whether the project is viable and worth pursuing. The next step is to design the factory layout, the production process and the quality control system. The factory layout should optimize the use of space, ensure safety and facilitate maintenance. The production process should be efficient, cost-effective and environmentally friendly. The quality control system should ensure that the products meet the standards and specifications of the customers. The final step is to obtain the necessary permits, licenses and approvals from the relevant authorities, such as the environmental protection agency, the fire department, the health department and the tax office. You should also secure the land, water and electricity supply for the factory.

Construction stage

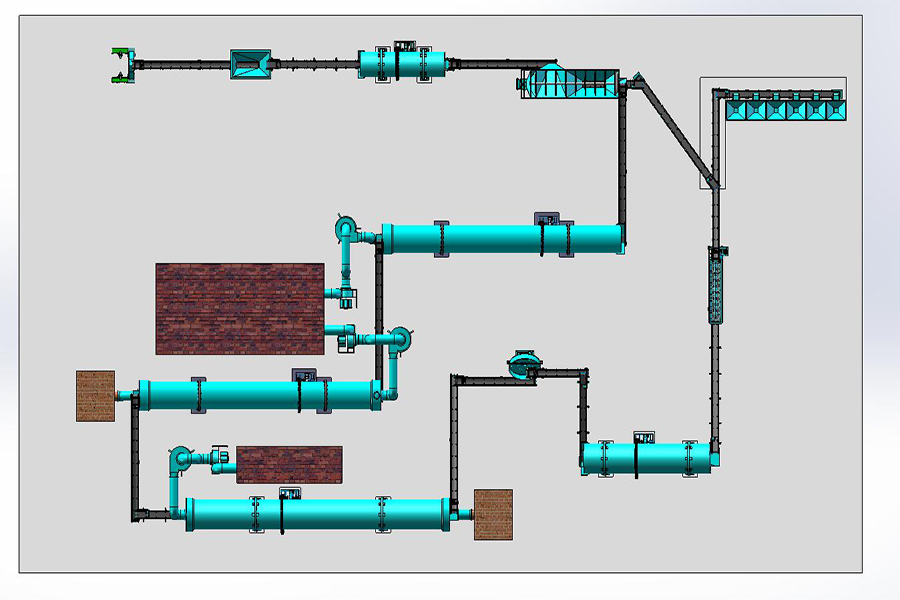

The construction stage involves building the factory infrastructure, installing the equipment and hiring the staff. The infrastructure includes the buildings, roads, drainage systems, pipelines, storage facilities and waste disposal facilities. The equipment includes the crushers, mixers, granulators, dryers, coolers, sieves, coating machines and packaging machines. The staff includes the managers, engineers, technicians, operators and workers. You should hire a reputable contractor to oversee the construction work and ensure that it meets the quality standards and deadlines. You should also conduct regular inspections and tests to monitor the progress and quality of the work.

Operation stage

The operation stage involves running the factory and producing the compound fertilizers. You should follow the standard operating procedures (SOPs) for each step of the production process and maintain a high level of hygiene and safety. You should also perform routine maintenance and repairs on the equipment and infrastructure to prevent breakdowns and accidents. You should keep track of the inventory of raw materials, finished products and waste materials. You should also keep records of the production data, such as the output, consumption, quality and cost. You should analyze these data to evaluate the performance and efficiency of the factory and identify areas for improvement. You should also establish good relationships with your suppliers, customers and stakeholders. You should communicate with them regularly and respond to their feedback and complaints. You should also comply with all the regulations and standards related to compound fertilizer production.

Conclusion

Establishing a factory to produce compound fertilizers is a complex and challenging project that requires careful planning, execution and management. However, it can also be a rewarding venture that can generate income and contribute to agricultural development. If you follow these steps and tips, you can successfully establish your own compound fertilizer factory.